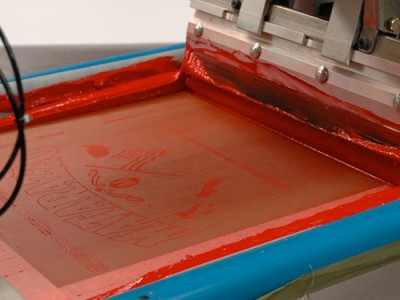

Custom Screen Printing on T-shirts and more.

Screen printing is time tested and inexpensive way to advertise and get your message across effectively. We offer both manual printing for small orders and automatic printing for larger orders.

We have over 20 years experience you can count on. Quality comes first at Xpress Screen printing. We insure all of our products meet our high standards. Our prints are crisp, vibrant and durable. We stand behind everything we print and always will. We guarantee it.

Prints from 1 to 12 colors. We can handle up to 12 different colors so you can let your creative juices flow. From mild to wild we do it all, including embroidery.

No surprises. You’ll receive a proofs along with a written estimate to approve before any work begins. We insure every order is accurate and delivered on time.

We’re here to help. We’re always available to help you with design help, garment selection and tasteful suggestions. We’re here for you when ever you need us.

Ordering is straight forward and easy.

- A short friendly consultation with customer via phone or email is made and job requirements are assessed. An estimate is then sent to customer.

- Customer approves job by returning the signed estimate via email or fax.

- Artwork is handled, either new or customer supplied. (We do require a small deposit before any new artwork is created unless terms have been established.)

- Art proofs are sent out to be approved. If changes are needed they are completed.

- Customer approves the artwork by returning the signed job proof via email or fax.

- Payment is handled and the job is scheduled.

- Job is completed and delivered. We can ship your order anywhere in the United States.

Easy peasy lemon squeezy. Call us today and lets get started on your order.

760-845-4170 or toll free at 800-382-6909

We currently do not publish our screen print pricing online. Please contact us to receive a detailed quote for your job.

Other shops publish their prices online, why not you? Because there are many different variables.

No job thats exactly the same as another. For instance, the quantity of your order, the brand , style and color of the garment you select, the number of print placements you choose, as well as the number of colors used, the ink type and the image print size all factor into the final price. Automated online pricing programs have difficulty factoring so many variables cannot not give accurate job quotes.

Personal interaction is the fastest and easiest way to find out what your needs are.

Please contact us at (858) 486-1035 for a quote or fill out our contact form for a detailed no-obligation quote.

A screen is what we use to print your artwork and each color we print gets a separate screen. If your art has four colors we’ll need four screens. A separate set of screens are needed for each individual print on a garment unless its the exact same print. If you have a 4 color large back print and a 2 color small front print you will need a total of 6 screens.

Films. $15 per film. This is a one time fee.*

Films are what we use to prepare or “burn” your screen. A film is a thin transparent sheet with an opaque image where the color to be printed will fall on the screen.

Art time. $50 per hour. This includes any revisions to existing artwork or creation of original artwork. It also covers any time used to color separate your artwork.

Color separations. Color separating is the process of converting a full color graphic into single color layers for use in the screen printing process. These single layers are output as films which are used to prepare screens for printing. On most output ready vector files this service is free. On more complicated images we charge the art time rate of $50 per hour.

Our two preferred file types are Adobe Illustrator files and Adobe Photoshop files. These are the most commonly used file types in screen printing. Illustrator files are vector based graphics and photoshop files are bitmap or raster images.

Whats the difference and why does it matter?

![]() Illustrator Files use vector graphics. A single vector is a line between two points.

Illustrator Files use vector graphics. A single vector is a line between two points.

Vectors can be used to create shapes, lines, polygons, in fact any shape imaginable. The software thinks of it as a mathematical formula- for example, the user creates a line on a 45º angle from point A to point B for a distance of 50mm and is 2mm wide.

The software draws the line based on this data rather than each pixel. Therefore vector graphics are infinitely scalable – if it’s 50mm in length or 5 metres in length the relationship between the points will always be the same.

Vector graphics are ideal for screen printing. A designer can create a vector graphic and that graphic can then be applied to anything from a business card to building signage with no loss of quality. However, vector cannot be used to efficiently draw photo images.

Illustrator files must have all fonts converted to outlines. This turns the fonts into vector graphics and eliminates any possible font conflicts or issues with missing fonts that you may have used and that we may not have.

Submitted images should use standard pantone colors instead of the standard illustrator color pallet so that we can accurately match ink colors.

![]() Photoshop files or raster images. Raster graphics, also known as bitmap graphics, is a digital image made from pixels which are points of colour and are commonly used on photo images.

Photoshop files or raster images. Raster graphics, also known as bitmap graphics, is a digital image made from pixels which are points of colour and are commonly used on photo images.

Raster graphics are resolution dependent – this means it cannot be scaled larger without losing quality.

This loss of quality makes images look pixelated (the ragged square-like look you see when a raster image is enlarged too far).

Images that are pulled off the web are not good images to use for screen printing. Web images are usually optimized to be as small as possible to keep their file size small and help a page load faster. This is great for a web page but not for printing. Please do not send us web images for printing.

If using raster images they must be created and submitted at the same size that they are to be printed. They need to be at a resolution of at least 200 dots per inch and no more than 300 dots per inch to keep file sizes manageable.

Whats the minimum order?

The standard minimum order is 24 pieces, We can do smaller runs on request with prior approval.

There are price breaks at starting at quantities of 48, 72, 144, 288 and 576 pcs.

Keep in mind that that it takes the same amount of time and materials to set up a screen printing press to print one shirt as it does for 10,000 pcs. The more you order the more you’ll save.

How large of an image can I print?

We can print up to 14″ wide by 17” tall for standard printing.

We can do 4″ wide by 16″ long on sleeves.

Jumbo printing is available on orders over 144 pcs.

Can I mix colors and styles?

Absolutly, as long as the ink colors in the design don’t change we can print your design on multiple colors without incurring extra charges.

Keep in mind some designs lend themselves to being printed on different colored shirts better than others. There are certain designs may need revisions or additional screens to print correctly on different colors or both dark and light shirts. This can usually be accomplished for nominal fee.

Mixing garment styles. If you need X amount of T-shirts and Y amount of Polo’s its not a problem as long as they are getting the exact same print.

When will my order be completed?

Our standard turn time is 10 working days from approval.

Almost all orders are completed in less than 10 days. If you need your order in less time just let us know. Most of the time we can complete your order much faster without extra fees. Usually within 5 days.

Rush Service.

We can do complete screen printing orders in as little as 48 hours on request. There is a 25% premium on rush orders plus any expedited shipping if needed. We advise you to place your order well in advance of your in hands date to avoid any unnecessary charges.

What forms of payment do you accept?

What is an underbase print?

An underbase or flash print is a layer of ink which is usually white, that gets printed under all the other ink colors when a design is printed on a dark shirt.

For example, yellow ink printed directly onto a black shirt will look very muted and dull. To counteract this, a thin layer of white ink is printed directly under under where the yellow ink is to be printed then “flash cured” while the shirt is still on the printing press. The yellow is then printed on top of the white resulting in a vibrant bright yellow vs. the muted yellow without the flash.

Think of it like the primer that goes on a car before before you paint it.

An underbase is needed whenever dark garments are being printed. Because it uses up a color station on the press and requires a screen to print, it counts as a color when calculating your cost.